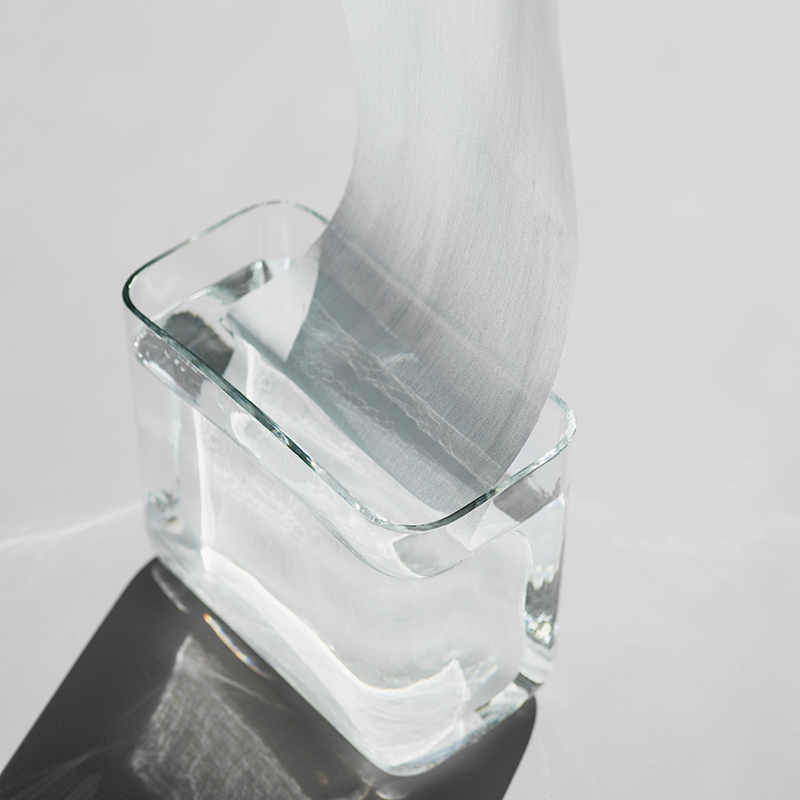

Microplastics are tiny pieces of plastic that pollute our oceans. These toxic microplastics slowly degrade, across approximately 600 years, ending up in aquatic life and through consumption, in the human body.

Circle textiles are toxin-free and release much less fibres into the water when washed. These are biodegradable within only a few days and are non-harmful to aquatic life or the human body.

Because of this, Circle textiles carry the coveted Cradle to Cradle Certified Gold.

UV radiation slowly breaks down the fibres of curtains, emitting small particles into the airflow. Circle textiles are toxin-free, from raw material to finished product, meaning that the risk of indoor air pollution is radically reduced for the benefit of our health.

The production of the fibres for Circle textiles require considerably fewer process steps than conventional polyester. This results in a considerable reduction of process energy, CO2 emissions and a positive impact on climate changes through reduced greenhouse-gases.

At end of life, Circle textiles may be composted and recycled into new fibres through an established take-back system. The textiles are processed at a composting facility where it takes 90 days to degrade the fibres to monomers*, which are used to make new fibres.

Other byproducts of the composting are humus, minerals, water, and biogas to be used in local agriculture and industrial applications.

In other words; no waste.

*monomer = a molecule that can react with molecules of the same kind to form a larger molecule. Monomers form the base of polymers.

There are no harmful chemicals or toxins in the entire Circle textiles process. This includes all dyes, coatings, and other ingredients.

In short; raw materials creating the best textile choice for our health and environment.

The few fibres that flow into the water are non-harmful and biodegradable within a few days on land and in the ocean.

Because of this, Circle textiles carry the coveted Cradle to Cradle Certified Gold.

The production of OceanSafe fibres, the basis for Cirle textiles, require 63% less CO2 equivalents than conventional polyester.*

In the manufacturing process, the energy used is either from renewable sources or CO2 emissions are offset.

*OceanSafe LCA data, based on Idemat database

Almedahls offers complete textile solutions for public and private spaces. We design and manufacture most of our products in Sweden as we have done for the past 178 years.